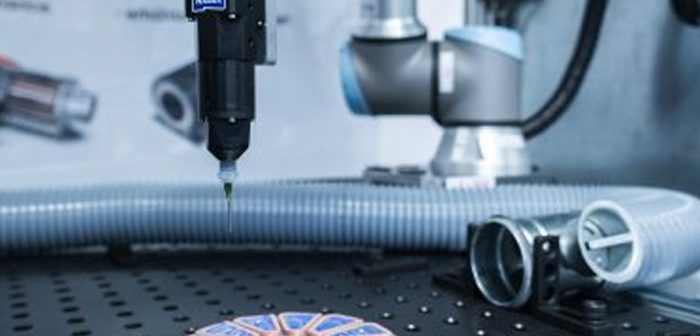

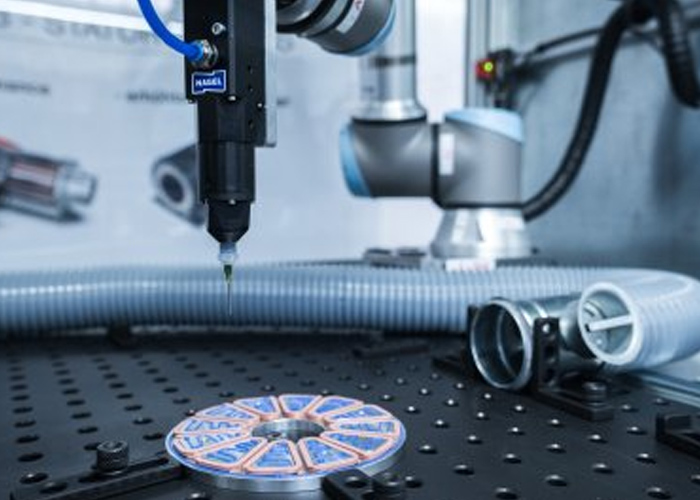

Nagel Technologies GmbH has unveiled the NaDos Robot Cell, a new robotic dispensing platform designed to deliver high precision and flexibility for industrial adhesive applications. The system is built around a UR 10e six-axis robot and combines plasma pretreatment, automated calibration and advanced digital path-planning tools to support both development environments and full-scale production.

The NaDos Robot Cell integrates plasma surface activation to improve adhesive bonding strength, while sensor-based calibration ensures accurate robot positioning during complex dispensing tasks. A built-in precision weighing system supports dosing from very small volumes through to high-flow applications, with optional two-component mixing. The platform is modular, allowing rapid tool changes between dispensers, grippers, screwdrivers, cameras and other modules, depending on the production requirement.

Nagel’s digital simulation technology enables users to define key points on a workpiece and automatically generate collision-aware motion paths. This approach is intended to reduce configuration time and improve process repeatability for both 2D and 3D contours. The robot cell accommodates industrial-scale components with a working area of 1,200 by 800 millimetres.

The system is aimed at manufacturers working with advanced adhesive processes, including applications in electric mobility such as stator bonding for axial flux motors. It is positioned as a flexible platform that can support prototype testing and transition smoothly into serial production. Nagel also notes that the cell can be integrated into wider manufacturing lines through existing partnerships with companies involved in coil bending, welding and impregnation processes.

As production requirements become more demanding and adhesive technologies more complex, systems such as the NaDos Robot Cell offer an option for automating high-precision bonding while reducing variability and setup time.